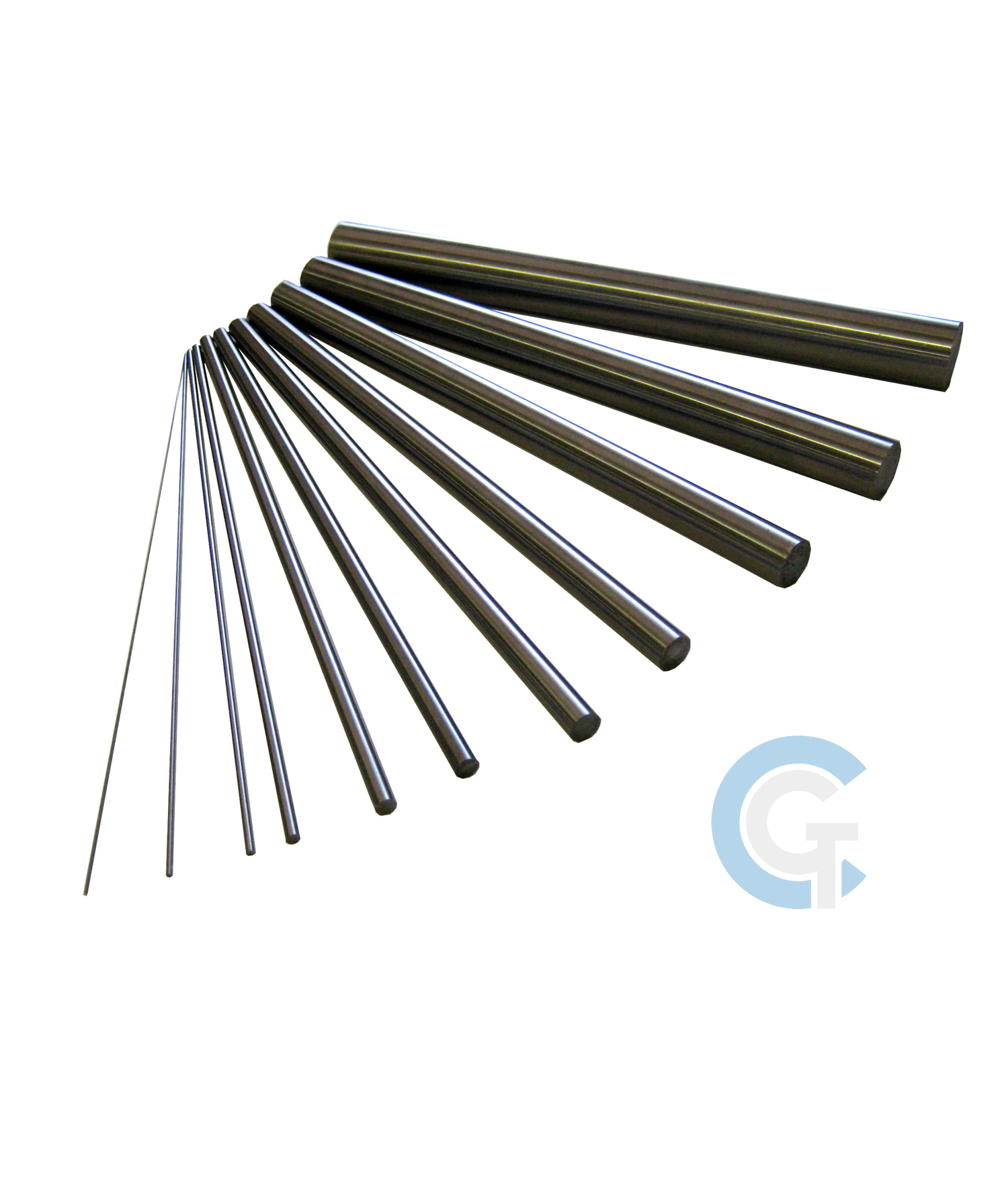

Imperial Silver Steel 13″ Long

£0.49 – £82.79 Inc. VAT

Imperial Silver Steel is available in all standard diameters and supplied in 13″, 1 metre and 2 metre lengths. Silver steel is a great multi purpose steel ground to very close tolerances with wide ranging applications. It contains a high carbon & chrome content which gives the material its toughness and shine.

Silver Steel is a product we specialise in and can offer bespoke sized on diameter and length which are on a make to order basis. If you require a data sheet with heat treatment instructions this can be downloaded here: Silver Steel Data Sheet

Reviews

There are no reviews yet.