FAQs

Here you’ll find a list of our most frequently asked questions. These FAQs are designed to provide a better understanding of the scope of services Coventry Grinders offer. For more information or support, or for any other enquiries, please get in touch via our contact page.

Gauge Plate / Ground Flat Stock

Gauge Plate is made from 01 grade tool steel and can achieve a hardness of 62° Rockwell C. Full heat treat instructions can be found on this download link; Gauge Plate Data Sheet

Yes they are both the same product made of 01 tool steel. Gauge Plate is the historical name for the product in the UK it stems from when engineers would refer to sizes as gauge.

Yes, here at Coventry Grinders we can make almost any non standard size, we also offer cut pieces so if your only looking for a 1 off small piece please email your enquiry and we will send you a quotation.

Unfortunately there is no real definitive flatness tolerance. The “flat” in ground flat stock purely means its not round. Flatness depends on thickness, 1mm thick material is difficult to make as it is so thin thus more susceptible to bowing. Thicker sizes tend to be more stable. An acceptable tolerance would be 1mm in 1000mm long. If you require a specific flatness tolerance email or call us to discuss this possibility.

Gauge Plate is supplied in an annealed condition to a maximum of 229HB – 21 Rockwell C. Annealing is a process in which the steel is heated to a specific temperature and allowed to cool slowly. This then softens the material allowing it to be cut and machined easier.

Unfortunately Gauge plate is manufactured in bulk from bar and cropped raw material pieces. Care is taken to achieve the best squareness possible but to ensure a tolerance could be achieved each peice would have to be ground & inspected on its own merits. This would be very time consuming and thus cost considerably more to produce.

Here at Coventry Grinders we are able to check the squareness of stock pieces if requested before ordering. We can also produce to a bespoke drawing requirement. Please contact us for this service.

Grinding Wheels & Abrasives

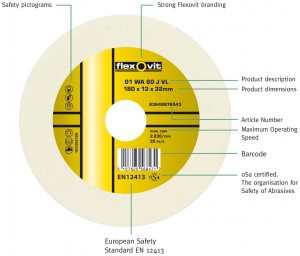

Labels can sometimes be confusing in understanding what type and grade of wheel you have. There can be batch numbers, speeds and product codes but there will always be the wheel specification on there. Each manufacturer have their own grades and with this information we can help you choose the right wheel for you. Please see this guide on how to identify.

The easiest way to understand this is the lower the number the coarser the grit of abrasive grain. A 24 grit size is very coarse and a 320 grit is fine. Each have their own uses, coarse for stock removal, fine grit for a good finish on the workpiece.

In precision grinding environment you will require a green silicon grinding wheel. Coventy Grinders offer a range of green silicon wheels for sale so please contact us for more information.

In fabrication industry you will require a grinding or cutting disc that is suitable for inox this will be on the label of the wheel. For applications using a flap disc these require a zirconia or ceramic grit content.

For precision grinding of hardened tool steels such as 01 & D2 you should use a ceramic grain wheel. These are normally sky blue in colour. There are degrees of ceramic wheel ranging from 10 -50%. Most common used are of a 30% content. ceramic grain fractures under the pressure of grinding, by doing so the grain reveals more sharp points to enable grinding. Conventional white grinding wheels that are made from aluminium oxide grain blunt rather than fracture meaing you have to dress the wheel more.

We recommend you dress the wheel with a clustter diamond for rough grinding / stock removal as this opens up the wheel more giving more sharper points to cut with. To achieve a good surface finish dress the wheel slowly with either the cluster diamond or a single point diamond.

We offer our own brand of ceramic wheels here: Coventry Grinders Ceramic Wheels

Norton SG ceramic wheels here:Norton SG ceramic wheels

Silver Steel

Unfortunately silver steel does not contain silver! Due to a high chrome content once ground gives the material a nice shiny finish. similar to silver.

Yes it can reach high hardness levels but can be brittle once hardened so using it as a punch would not be suitable. A data sheet containing heat treatment instructions can be downloaded here: Silver Steel Data Sheet

Yes it is and this British standard ensures that the product is made to a close tolerance. Other European specifications have a bigger tolerance so if you need to guarantee a close tolerance then our Silver Steel is for you.

Yes we do, it would be subject to a minimum quantity of your required diameter. Please email or call us with your enquiry.

Key Steel

Our key Steel is made from EN8 material supplied in a bright drawn condition.

Tolerances change according to size, a larger tolerance is on bigger sizes. Imperial sizes are a plus tolerance, metric sizes are a minus tolerance. Tolerance ranges can be downloaded here: Imperial Key Steel Tolerance Metric Key Steel Tolerance

ISO 9001:2008 Certification

Coventry Grinders is proud to have achieved ISO 9001;2015 status. This shows our dedication to achieving high standards of service that our customers now expect. You can download our latest ISO Certificate here: