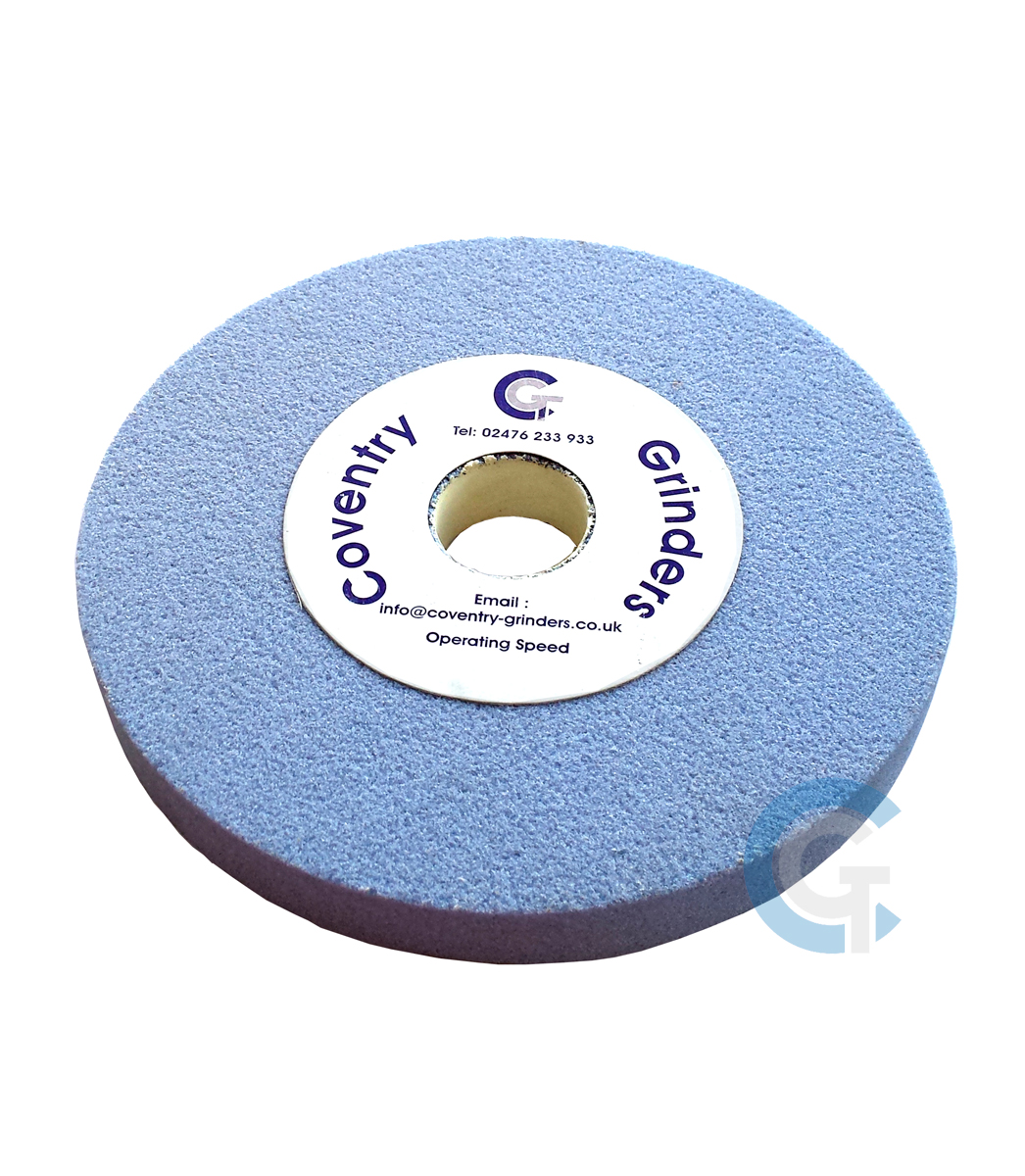

Coventry Grinders Ceramic Grinding Wheels

£12.00 – £312.00 Inc. VAT

This is Coventry Grinders’ own brand of ceramic grinding wheel designed for grinding hardened tool steel. Due to its 30% ceramic content higher stock removal can be gained combined with less heat will give it improved performance over standard white aluminium oxide wheels.

This is our own brand of ceramic grinding wheel. Made of 30% genuine ceramic abrasive. This grinding wheel is ideally suited to grind harder tool steel materials such as hardened D2 or 01 tool steels but can also be used on softer materials with the same performing results. The ceramic content of the grinding wheel aids to keep a sharp edge, higher stock removal and cool cutting. This grinding wheel can be used with or with or without coolant. For non forming surface grinding applications even better performance can be gained by using a cluster diamond dresser.

Ceramic grain technology works by how the grain wares under contact on the work piece. Aluminium oxide grains blunt under use and require more dressing of the wheel to keep a cutting edge. Ceramic grain by comparison, fractures under pressure on the work piece and this results in new sharp edges of the grain being revealed thus keeping a cutting edge for longer. Keeping a sharp grains aids in the performance on hard or difficult materials.

This is our most popular grinding wheel that we offer at a low cost with excellent performance. If you have not tried one we believe you will be surprised on the performance enhancement over a conventional white grinding wheel.

Here is a video showing our wheel on hardened D2 and showing the high cut rate the wheel is able to take. Ceramic wheels rely on pressure to work better. For many skilled grinders this is counter intuitive but this video demonstrates surface grinding at cut feeds of 0.002″, 0.003″ & 0.005″

1 review for Coventry Grinders Ceramic Grinding Wheels

Add a review Cancel reply

Related products

Our Grinding Wheels

Our Grinding Wheels

Our Grinding Wheels

Our Grinding Wheels

Our Grinding Wheels

Our Grinding Wheels

Our Grinding Wheels

Our Grinding Wheels

Jamie Holland (verified owner) –

This wheel is much better than the Aluminium Oxide wheel